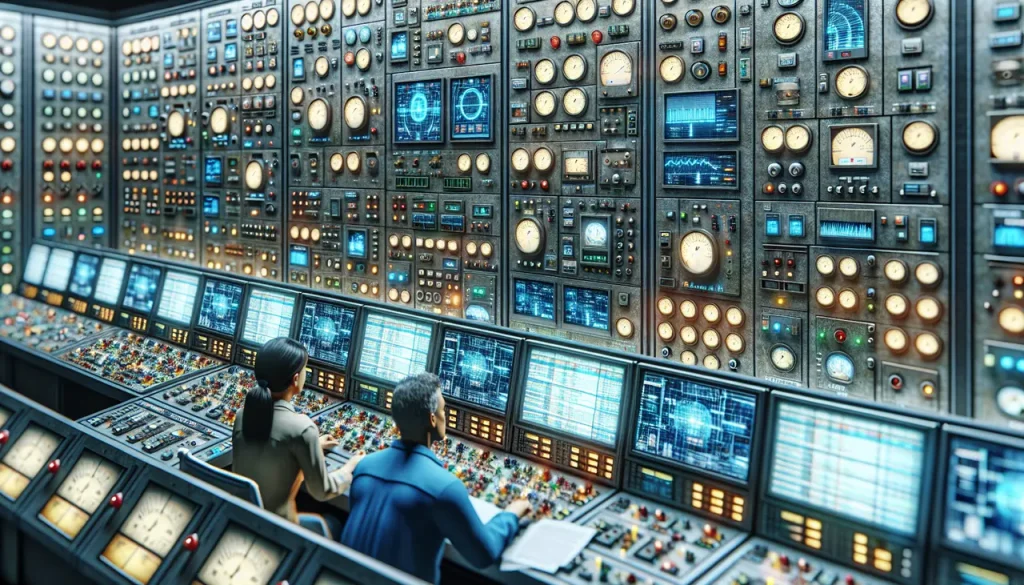

Distributed Control Systems (DCS) are crucial for managing industrial processes efficiently. However, they come with their own set of challenges. In this blog, we’ll explore ten common issues that arise with DCS and provide practical solutions to fix them, ensuring your systems run smoothly and effectively.

1. System Integration Challenges

Integrating various components into a unified DCS can be complex. To tackle this, ensure thorough planning and use compatible hardware and software from reputable suppliers. An important step in overcoming integration challenges is conducting an engineering study to evaluate the obsolescence and longevity of the plant’s control system, as well as performing a cost-benefit analysis for various migration strategies. Utilizing simulation tools such as Honeywell Experion PKS control system can further aid in understanding the integration dynamics. By documenting the plant control system comprehensively and developing a vendor support timeline, you can identify obsolete equipment and DCS reliability issues, facilitating a seamless integration process.

Moreover, consider leveraging the expertise of engineering professionals in control systems integration. At Industrial Design Solutions, we offer detailed engineering studies and customized migration solutions to assist with integration. Our services include analyzing hardware, engineering, and construction costs, enabling you to make informed decisions about the most efficient modernization strategies tailored to your operations. This planning reduces the risk of integration failures and ensures smooth transitions to improved DCS platforms.

2. Communication Failures

Communication issues between devices can cripple a DCS. Regularly update firmware and use redundancy in network paths to prevent single points of failure. Employing reliable communication protocols such as Ethernet and Fieldbus can strengthen the network’s resilience. By frequently monitoring the network for latency and packet losses, you can preemptively diagnose and address communication issues before they escalate. Utilizing Network Redundancy practices within your DCS architecture ensures that data flow remains uninterrupted even if part of the network fails.

Another effective way to enhance network reliability is by implementing a robust network management strategy. This encompasses proper configuration and maintenance of network devices. At Industrial Design Solutions, we specialize in optimizing control system IT support, including the configuration and maintenance of network devices. Ensuring that antivirus systems are updated and patch management practices are followed can prevent cybersecurity threats that might compromise communication within the DCS network.

3. Latency Problems

High latency can disrupt real-time operations. Optimize your network and use prioritized traffic management to reduce delays. Efficient data handling mechanisms can help manage latency issues effectively. For instance, implementing data prioritization techniques ensures that critical control messages are transmitted with the least delay. Employing advanced networking hardware that supports low-latency protocols is another significant step towards minimizing latency in your DCS.

A comprehensive network analysis can reveal bottlenecks causing latency. This should be combined with strategic placement of controllers and sensors to optimize data flow. At Industrial Design Solutions, our control engineering team can help you develop advanced control strategies and optimize your DCS architecture to ensure low-latency communication. Properly tuning the system for real-time performance can make a substantial difference.

4. Data Overload

Handling vast amounts of data can be overwhelming. Implement efficient data filtering and storage solutions to manage and analyze information effectively. Setting up Historian integration can streamline data storage and retrieval processes. This integration also aids in effective data management, as historians like Honeywell PHD or other specialized systems can store real-time data efficiently. Determining which data is critical and needs immediate processing versus data that can be archived can help manage data overload.

Efficient data management also involves setting up automated data processing and analysis tools to filter and sort data based on priority and relevance. For comprehensive data storage and analysis solutions, consider the services at Industrial Design Solutions. Our expertise in historian integration, cloud control system integration, and advanced data management techniques can enhance your ability to handle and leverage vast datasets within your DCS.

5. Security Vulnerabilities

Cybersecurity is a significant concern. Deploy robust security measures including firewalls, encryption, and regular security audits to protect your DCS. Implementing a well-configured antivirus system, detailed monitoring of network traffic, and stringent access control measures are crucial steps. Incorporating multilayered security protocols can significantly strengthen your system’s defense against cyber threats. Employing security frameworks in line with industry standards can also bolster your cybersecurity defenses.

Additionally, partnering with an experienced IT support provider ensures ongoing security maintenance and updates. Industrial Design Solutions offers specialized IT support services, including antivirus management and patch management, to keep your DCS secure. Regularly scheduled security audits and adopting proactive cybersecurity strategies can help detect and mitigate vulnerabilities before they lead to significant issues.

6. Hardware Failures

Component failures can cause major disruptions. Regular maintenance and using high-quality, reliable hardware can help minimize these issues. Adopting a proactive maintenance strategy that includes regular inspections and timely repairs can extend the lifespan of your hardware components. Ensure that all hardware components are sourced from reputable suppliers known for their reliability and quality.

A detailed maintenance routine helps in the early detection of potential hardware failures. Services like those offered by Industrial Design Solutions include installing and maintaining essential hardware components to ensure optimal system performance. Regular updates and rigorous testing of hardware are key to avoiding untimely failures.

7. Software Bugs

Bugs in software can lead to unexpected system behavior. Keep software updated and carry out thorough testing before deployment. Adopting a systematic approach to software development and incorporating rigorous testing procedures can identify and rectify bugs early in the development cycle. Implementing version control and change management practices ensures that updates and patches are applied consistently across the system.

A focused effort on debugging and software quality assurance can minimize software-induced disruptions. Leveraging the expertise of control engineering professionals, like those at Industrial Design Solutions, ensures that your DCS software is reliable, secure, and efficiently performs the required control functions. Regular software audits and validation tests are critical practices to maintain software integrity.

8. Operator Errors

Human errors can have significant impacts. Provide comprehensive training and support to operators to ensure they are well-prepared to manage the DCS. Developing structured training programs tailored to the specific needs of your operators can significantly reduce the likelihood of operator errors. Incorporating hands-on training sessions, simulation-based learning, and regular refresher courses will enhance the operators’ confidence and proficiency.

Effective training programs should combine theoretical knowledge and practical skills training. At Industrial Design Solutions, we offer extensive training and support programs designed to empower operators with the necessary skills to manage complex control systems efficiently. Continuous evaluation and feedback mechanisms within the training program can further enhance operator performance.

9. Scalability Issues

As your needs grow, your DCS must scale accordingly. Plan for scalability from the outset and invest in flexible, modular systems that can grow with your operations. Designing a scalable architecture that incorporates modular components enables your system to expand seamlessly. Preparing a detailed scalability plan and regularly reviewing it can ensure that your DCS meets evolving demands without compromising performance.

Investing in scalable solutions such as those provided by Industrial Design Solutions can ensure your system remains agile and capable of adapting to future needs. Modular hardware and software solutions allow for incremental upgrades and expansions, minimizing disruptions and costs associated with large-scale overhauls.

10. Lack of Vendor Support

Having no vendor support can leave you stuck during critical failures. Choose vendors with a good track record of support and responsiveness. Consistent and reliable vendor support is vital for maintaining the operational integrity of your DCS. Regularly engaging with your vendor and staying updated on the latest support services they offer will ensure you have robust backup during emergencies.

At Industrial Design Solutions, we pride ourselves on providing exceptional support for all your control system needs. Ensuring a strong partnership with your vendor, along with access to expert guidance and quick response times, guarantees you have the support required to address and resolve any issues promptly.